Mesin uji tarik baja Otomatis kap. 500/1000kN

21/03/2018

Mesin uji Marshall/indirect tensile untuk Aspal

24/03/2018UTM Mesin Uji tarik baja tulangan 700kN

Mesin Uji Tarik Baja dan Tekan Beton dengan kapasitas 700, 1000 kN

Brand : Controls – Italia

Standard : EN ISO 6892 | EN ISO 7500-1 | ASTM A370 | EN ISO 15630-1

Kode Barang : 70 – T07P02

Fitur Utama :

- Menggunakan 4 Kolom KakuRUGGED FOUR COLUMN FRAME

Menggunakan Desain frame 4 Kolom kaku dengan jarak ruang vertikal yang cocok untuk uji tarik baja dan uji tekan. - Range aksesoris yang luas

Tersedia untuk berbagai macam pengujian termasuk Extensometers, Transverse dan perangkat uji Bending untuk Baja, Tekan dan Indirect tensile pada Beton, etc. - Dilengkapi Dengan Software

Pengolahan Data dan Hasil elaborasi menggunakan Software yang sangat luas aplikasinya.

Deskripsi Umum :

Tujuan :

Mesin ini tergolong dalam kategori UTM, UTM masih mempunyai arti yang luas karena berasal dari singkatan Universal Testing Machine yang mempunyai pengertian siangkat mesin untuk berbagai macam pengujian.

UTM yang kami jelaskan pada halaman ini mempunyai sepesifikasi fungsi untuk digunakan pada Uji Tarik dan Tekan pada sampel Baja (tulangan) dan beton.

Mesin :

Flexibilitas tinggi yang dapat melakukan berabagai macam pengujian:

- Baja

- Tensile tests pada Baja tulangan sampai diameter 60mm.

- Tensile test pada baja pipih/plat sampai ukuran 60 x 90 mm

- Transverse tests pada spesimen baja

- Bend and re-bend (tekuk) test pada spesimen baja

- Shear tests on rounds

- Beton

- Uji Tekan pada sampel Kubus dan silinder

- Uji Indirect tensile pada silinder, Kubus dan paving blocks

- Various(lainnya)

- Uji tekan pada Batu, Bata, refractories etc.

- Uji tarik pada Nut bolt(baut)

- Tensile test on headed and shouldered specimens

UTM model ini dikendalikan menggunakan unit UTM AUTO dan dilengkapi dengan penjepit manual atas dan bawah, beberapa grip untuk baja tulangan dan baja pipih, transverse test attachment dan Transducer berpresisi tinggi.

Frame Pembebanan

Terdiri dari 4 Kolom kaku dengan dengan tiga balok kokoh(crossheads) dan stabil : satu pada terletak paling atas yang tersambung dari kolom utama dari bawah; Satu Ditengah tengah, bergerak ke kolom ulir, dapat diatur menggunakan mesin pengatur melalui panel tombol khusus untuk itu, untuk melakukan uji tekan dan tarik pada ruang vertikal bagian bawah dikendalikan dengan Piston terpusat. Sudah termasuk Grip dan gigitan. Pengait uji tarik di operasikan secara manual. Untuk uji tekan dilakukan diantara Batang bawah dan batang tengah dengan menggunakan aksesoris yang sesuai.

Power and control console – UTM AUTO

Konsol Daya dan kendali mengguanakan “UTM AUTO” yang mempunyai desain irit ruang dengan pijakan kecil yang memuat unit power hidrolik dan perangkat elektronik.

Secara otomatis menjalankan uji tarik baja, tekan beton, split beton dan lainnya(dengan menggunakan aksesoris yang berkaitan). Silahkan melihat aksesoris.

Fitur Keselamatan :

- Katup tekanan yang akan berhenti secara otomatis ketika tekanan oli mencapai batas.

- Tombol perpindahan maximum untuk mengendalikan batang(crosshead).

- Tombol berhenti darurat

Spesifikasi Teknis :

TECHNICAL SPECIFICATIONS TABLE

| Model | HTP-700 | HTP-1000 | |

| Code | 70-T07P02 | 70-T10P02 | |

| Cap. | 700 kN | 1000 kN | |

| Load sensor: | Pressure Transducer | Pressure Transducer | |

| For rounds up to mm dia.: | 70 | 70 | |

| Set of grips for rounds dia. mm: | 12 to 30 | 12 to 30 | |

| 30 to 50 | 30 to 50 | ||

| 50 to 70 | 50 to 70 | ||

| For flats dim. mm. : | 22 x 70 | 22 x 70 | |

| 22 to 44 x 70 | 22 to 44 x 70 | ||

| 44 to 65 x 70 | 44 to 65 x 70 | ||

| Piston travel mm. | 250 | 250 | |

| Max adjustable tensile daylight mm: | 50-850 | 50-850 | |

| Max daylight between grippers [mm]* | 600 | 600 | |

| Max. compression daylight (without accessories) mm.: | 0-850 | 0-850 | |

| Horizontal daylight mm.: | 750 | 750 | |

| Maximum piston speed (no load condition) mm/min: | 55 | 55 | |

| Crosshead adjustable speed [mm/min] | 360 @50 Hz | 360 @50 Hz | |

| 430 @60 Hz | 430 @60 Hz | ||

| Load resolution [kN] | 0.01 | 0.01 | |

| Crosshead displacement resolution [mm] | 0.01 | 0.01 | |

| Machine class 1 range (EN ISO 7500-1) | 50-700 kN | 50-1000 kN | |

| Overall dimensions: Frame, LxDxH [m] Console, LxDxH [m] |

1,1 x 0,66 x 3,0/3,25 0,8 x 0,9 x 1,55 |

1,1 x 0,66 x 3,0/3,25 0,8 x 0,9 x 1,55 |

|

| Weight approx.: Frame kg Console kg |

3700kg 180 kg |

3700kg 180 kg |

|

*Max distance between grips to exploit the full piston travel

UTM-AUTO POWER AND CONTROL CONSOLE

Hardware and firmware

- 000 points effective resolution

- Closed-loop P.I.D.control

- 2 channels for load sensors

- 1 channel to measure crosshead separation travel with high precision displacement transducer (included)

- 1 channel to measure rebars elongation with extensometers (see Accessories)

- digital linearization of the calibration curve (multi-coefficient)

Tensile test:

- Automatic test execution under load/stress control and grips separation control (by using the displacement transducer supplied with the machine) with closed loop PID control

- Simultaneous display of load, stress and specimen elongation

- Possibility to overlap two elongation/stress graphs:

- one obtained with the included displacement transducer measuring crosshead separation travel

- one obtained with an optional extensometer (coaxial or universal)

- Graphical test data option showing the load/elongation curve

Compression test:

- Automatic test execution of compression tests with closed loop PID control

- Simultaneous display of load and stress, load/time graph

Hydraulics

- Dual stage pump: centrifugal low pressure for fast approach (max. flow rate 2.5 l/min ) automatically switching to radial multi- piston high pressure (max. flow rate 0.9 l/min) for loading

- DC motor 1100 W

- Maximum working pressure 700 bar

- Oil tank capacity 9 l

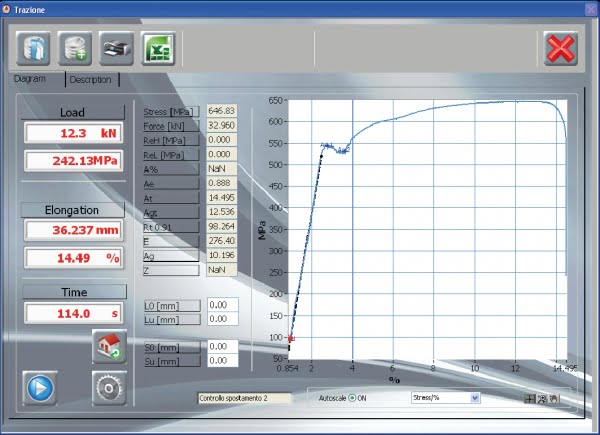

Software

UTS Light data acquisition and processing software (included) for tensile test according to EN Standard allowing:

- Input of specimen identification, test and name of customer

- real time downloading of test data

- simultaneous display of stress/time and stress/elongation by using coaxial extensometer series or universal extensometer series (see Accessories) or displacment transducer reading crosshead separation travel (included)

- elaboration of tension test results once test is completed: ReH, ReL or Rp, final elongation, etc. in conformity to EN ISO 6892-1 (method B) and EN 15630-1 (for steel rebars) when extensometer is adopted

- unit of measurement: kN, mm, MPa

- printout of test reports

- multi-language software

Ordering Info :

70-T07P02

Automatic Universal Testing Machine, 700 kN cap. UTM AUTO control console. For tensile/transverse/bend and re-bend tests on steel and compression/indirect tensile tests on concrete and other materials.

380 V, 50-60Hz, 3ph

Aksesoris :

ELECTRONIC COAXIAL EXTENSOMETERS

These extensometers are basically made from three separate aluminium tubular sections, joined telescopically to one another. The middle section, delimited by the larger diameter, determines the measuring base, which is 5 times the diameter of the specimen. The two end sections consist of two mechanisms for gripping the specimen. One carries the electrical extensometer, the other an anvil.

70-C0961/A2

Coaxial electronic extensometer for round specimens from 5 to 11,5 mm dia.

70-C0961/B2

Coaxial electronic extensometer for round specimens from 11 to 18 mm dia.

70-C0961/C2

Coaxial electronic extensometer for round specimens from 17,5 to 26 mm dia.

70-C0961/D1

Coaxial electronic extensometer for round specimens from 26 to 36 mm dia.

70-C0961/E

Coaxial electronic extensometer to measure the elongation of strands from 9 to 15,2mm dia. up to failure.

Gauge length: 600 mm; Max travel: 50 mm.

UNIVERSAL EXTENSOMETERS

70-C0954/C1

Standard electronic extensometer.

Fitted with high precision electronic linear transducer. Maximum travel 10 mm, measuring base 200 mm. It has to be removed before sample failure.

70-C0953/C

Mechanical extensometer. Suitable flat samples up to 40 x 40 mm, rounds from 0.4 mm to 40 mm diameter. Base length: 50, 100 and 200 mm. Dial gauge 10 x 0.01mm.

SMALL AND BIG SHEAR TEST ATTACHMENT

70-T10/SH

Small and big shear test attachment.

SHOULDERED AND THREADED SPECIMENS TEST ATTACHMENT

Standard: ASTM E8

70-T10P/ST

Shouldered and Threaded specimens test accessory.

Suitable for 70-T07P0x and 70-T10P0x models.

NUT AND BOLT TEST ATTACHMENT

Standards: ASTM F606, ISO 898-1

70-T10P/NB

Nut and bolt test accessory for specimens from M12, M14, M16, M18, M20, M22, M24, M27, M30, M33.

Suitable for 70-T07P0x and 70-T10P0x models.

COMMON 180° & BEND REBEND TEST ATTACHMENT

Standards: ASTM A615, EN 10080

70-T10/BEN

Common 180° & Bend Rebend Test attachment for bar up to 40 mm dia.

70-T10/50

Loading element dia. 50 mm

N.B. loading elements ranging from dia.16mm up to dia.320mm available on request.

GRIPS FOR STRAND WIRES

70-T10P/SW

Set of grips for stands testing.

Suitable for 70-T07P0x and 70-T10P0x models.

COMPRESSION TESTS ON CONCRETE SPECIMENS

Standards: ASTM C39, AASHTO T22

70-T10/CC

Set of compression platens 216 mm dia., with spherical seats, for compression tests on concrete cubes up to 150 mm and cylinders up to dia. 160 x 320 mm.

SPLITTING TEST (INDIRECT TENSILE) ON CONCRETE SPECIMENS

Standards: ASTM C496, EN 1338, EN 12390-6

50-C9000/B

Splitting tensile test device for cylinders up to dia. 160×320 mm, conforming to ASTM C496 and EN 12390-6.

Weight approx..: 28 kg

50-C9000/A

Splitting tensile test device for cylinders dia. 250×500 mm, conforming to EN 12390-6.

Weight approx..: 50 kg

50-C9070/B

Splitting tensile test device for cubes up to 150 and

block pavers conforming to EN 1338 and EN 12390-6.

Weight approx..: 28 kg

50-C9002

Hardboard packing strips 4x15x345 mm to EN1338 and EN 12390-6. Pack of 50.

50-C9002/A

Plywood packing strips 3x25x345 mm to ASTM C496. Pack of 50.

50-C9001/A

Hardboard packing strips 4x15x550 mm for 50-C9000/A. Pack of 50.

Price : Call For Info

Yudhistira

Hp. 0811 188 6845; 0818 0816 0634(WA)

Email : naysite2@gmail.com;

Reviews

There are no reviews yet.