Alat ukur keretakan Struktur

15/03/2019

Mesin uji tekan beton Silinder dan kubus – Otomatis

28/05/2019Alat Uji Geser Mekanika Tanah dengan sistem Otomatis

Automatic shear testing machine SHEARMATIC EmS

Brand/Supplied From : Wykeheam Farrance/Controls – Italy

Standard : ASTM D3080(Setara dengan SNI 2813 : 2008), AASHTO T236 (Setara dengan SNI 3420:2016), BS 1377:7, CEN-ISO/TS 17892-10, NF P94-071

Model : 27-WF21E80

General Descriptions :

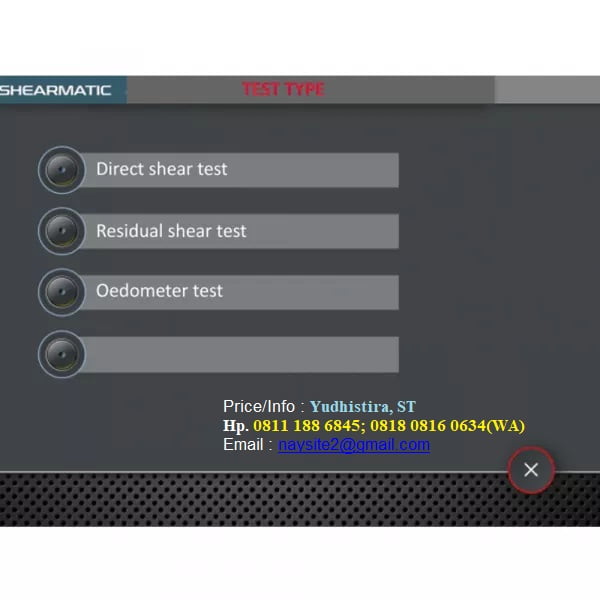

Shearmatic EmS is a standalone automatic machine with Electromechanic Servoactuation for direct/residual shear testing. It can also automatically perform the oedometric consolidation tests using the dedicated accessories. It incorporates two high-resolution stepper motors with high precision transmissions.

It features a closed loop PID control optimized for automatic test performance at the touch of a button, dead weights and air compressor are no more necessary.

The user interface is based on a large 6” touchscreen colour display permitting to start, pause and stop the test, to choose the data recording mode, to show the readings during the test execution and to carry out the transducers calibration.

The axial transmission of the horizontal force is accurately ensured by a straight connection between shear box, shaft and load cell. This design avoids the load measurement inaccuracies occurring with the widely used “swan neck” basic design.

A high quality techno-polymeric material has been adopted for the carriage of the shear box, offering excellent resistance to corrosion, wear and tear and to the chemicals often mixed with the soil specimens. Furthermore, this polymeric carriage is lightweight and easy to clean.

The digital controller reads and processes the vertical and horizontal forces and displacement readings and drives the motor accordingly for the proper automatic test execution under closed loop PID control.

The machine is supplied complete with the following transducers:

- 2 x 10 kN capacity load cells

- 11 mm displacement transducer

- 25 mm displacement transducer

In addition, a dedicated software (to be ordered separately) allows the remote control from a PC of multiple Shearmatic Ems machines. When the remote control mode is used, the PC software becomes the user interface and manages the main functions as well as the channels calibration by linear, polynomial and multi-coefficient curves.

Main Features :

- Electromechanical servoactuation. Dead weights and air compressor are not required making the test easy and accurate

- User interface 6” touch screen colour display for numerical and graphical plotting of the readings

- Maximum vertical force: 10 kN

- Maximum horizontal force: 10 kN

- Two displacement transducers measuring vertical settlement and horizontal displacement

- Two load cells measuring vertical and horizontal force

- Vertical force load cell directly mounted on the loading tip assuring high accuracy of the readings and of the control signal

- Infinitely variable speed from 0.00001 to 15.00000 mm/min

- High stiffness load chain shear box – driving head – load cell

- USB pen drive for unlimited storage capacity and TXT format data output

- Optional PC control via LAN port and dedicated software

- Sturdy shear box techno-polymeric carriage untouchable by corrosion

- Test velocity and travel (forward and reverse) adjustable(residual shear test)

- Number of consolidation steps adjustable from 1 to 99 and number of shear cycles adjustable from 1 to 50

- Axial force steps can be applied instantaneously as required by the standard

- Also suitable for the oedometric consolidation using typical consolidation cells

- Specific and independent data recording for consolidation and failure stages

Technical Specifications :

- Maximum vertical force: 10 kN

- Maximum horizontal force: 10 kN

- Max horizontal travel: 23 mm

- Max Vertical travel: 12.8 mm

- Test speed: from 0.00001 to 15.00000 mm/min

- Maximum number of consolidation steps: 99

- Maximum nuber of shear cycles: 50

- Weight approx.: 60 kg

- Sample type and size: up to 100 mm square or round

- Dimensions approx.. [lxhxd]: 990x550x350 mm

- Multivoltage – Multifrequency power supply 230 V, 50 Hz or 110 V, 60 Hz

Ordering Info :

27-WF21E80 SHEARMATIC EmS – Electromechanical Servoactuated technology, automatic direct and residual shear testing machine. 220-100 V / 50-60 Hz / 1 PH

Accessories :

Shear Box Assembly

27-WF0215/B

Shear box assembly for 60 mm square specimens

27-WF0216/B

Shear box assembly for 100 mm square specimens

27-WF0217/B

Shear box assembly for 50 mm dia. round specimens

27-WF0218/B

Shear box assembly for 60 mm dia. round specimens

27-WF0219/B

Shear box assembly for 63.5 mm dia. round specimens

27-WF0222/B

Shear box assembly for 100 mm dia. round specimens

Accessories for shear box

| Box model 27- | WF0215/B | WF0216/B | WF0217/B | WF0218/B | WF0219/B | WF0222/B |

| Part description27- | ||||||

| Sample cutter* | WF0215/B7 | WF0216/B7 | WF0217/B7 | WF0218/B7 | WF0219/B7 | WF0222/B7 |

| Extrusion dolly* | WF0215/8 | WF0216/8 | WF0217/8 | WF0218/8 | WF0219/8 | WF0222/8 |

Spare parts for shear box assemblies

| Box model 27- | WF0215/B | WF0216/B | WF0217/B | WF0218/B | WF0219/B | WF0222/B |

| Part description27- | ||||||

| Loading pad | WF0215/B2 | WF0216/B2 | WF0217/B2 | WF0218/B2 | WF0219/B2 | WF0222/B2 |

| Retaining plate | WF0215/B3 | WF0216/B3 | WF0217/B3 | WF0218/B3 | WF0219/B3 | WF0222/B3 |

| Porous plate | WF0215/4 | WF0216/4 | WF0217/4 | WF0218/4 | WF0219/4 | WF0222/4 |

| Plane grid** | WF0215/B5 | WF0216/B5 | WF0217/B5 | WF0218/B5 | WF0219/B5 | WF0222/B5 |

| Perforated grid** | WF0215/B6 | WF0216/B6 | WF0217/B6 | WF0218/B6 | WF0219/B6 | WF0222/B6 |

*Not supplied with the shear box. To be ordered separately

**Two pieces supplied with the shear box

Accessories for consolidation test

27-WF21E80/C

Accessories for the automatic performance of the consolidation test with the electro-mechanical direct and residual shear apparatus SHEARMATIC EmS. Consolidation cell not included (to be ordered separately)

Software

27-WF21E80/SW

PC Software for remote control and data acquisition from Shearmatic EmS machines, multiple units connectable to a single PC. Key features: remote control of the main functions, sensors’ calibration, numerical and graphical displaying of results, storage of test and calibration data.

Data processing template

30-WF6016/T2

Direct and residual Shear Geo-Analysis template conforming to BS 1377:7

30-WF6016/T9

Direct and residual Shear Geo-Analysis template conforming to ASTM D3080

Price : Call For Info

Yudhistira, ST

Hp. 0811 188 6845; 0818 0816 0634(WA)

Email : naysite2@gmail.com

Reviews

There are no reviews yet.