Mesin Uji Tekan Beton 3000kN Digital (Otomatis) dengan Printer dengan Frame General

11/03/2017

Alat Uji Hammer Test 58-C0181/C

12/03/2017Mesin Uji Tekan Beton Full Otomatis Tanpa Tuas – Rangka EN

Mesin Uji Tekan Beton Full Otomatis Tanpa Tuas – Rangka EN

Merk/Di suplai dari : Controls – Italy

Kode Barang : 50 – C46F02

Deskripsi Umum:

AUTOMAX PRO merupakan mesin uji tekan beton Seri tertinggi yang dibuat oleh CONTROLS dengan fitur Full Otomatis tanpa tuas.

Kapasitas : 2000kN, 3000kN, 4000kN, 5000kN

Hydraulics

- DC motor, 720W, 50-60Hz

- Maximum working pressure 700 bar

- Load/unload electrovalve for test execution via display/PC and automatic stop at specimen failure

- Active control of up to 4 frames by selection via display/PC (third and fourth frame as option). See accessories.

- ES Energy Saving technology to reduce the power consumption and enable silent operation

Hardware

- 524,000 points high-resolution/stability analog channels

- 4 channels for load sensors

- Control frequency 250 Hz

- Sampling frequency 250 Hz

- 7”, 800 x 480 pixel, 16 M colors, icon-driven capacitive sensing touchscreen graphic display

- Unlimited storage capacity for test data on internal 16 GB SD card

- USB port for test data storage on external USB memory stick and for firmware upgrade

- Ethernet port for PC / Internet /network communication

- Optional integrated graphic printer including Load-Time plot

- RS 232 port for data downloading in ASCII format

Firmware

- Execution of compression, flexure, indirect tensile, ACV tests in automatic mode with load rate controlled by a closed-loop P.I.D. system

- Execution of loading ramps with the possibility to manually increase or decrease the test speed during the test

- Pause command to maintain steady load can be enabled at a pre-set value before the test or as required while testing

- Simultaneous display of load, specific load, actual load rate, load/time graph

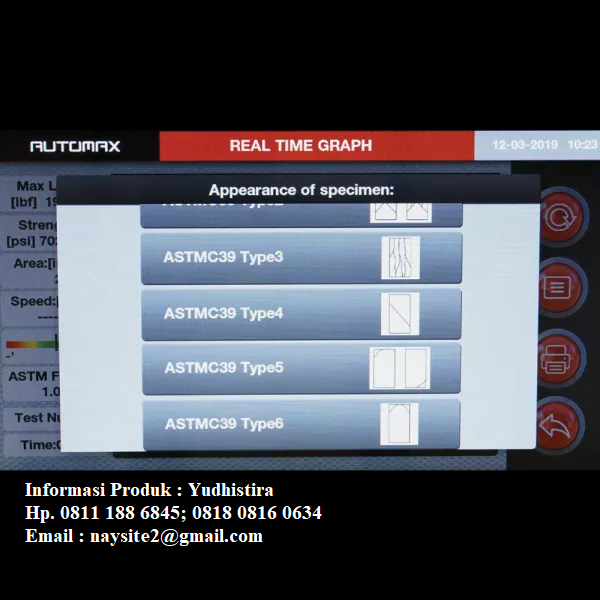

- Saving of the specimen failure type (to EN or ASTM) in the test results

- Download data to internal printer (optional) or to PC via RS 232 port or to USB memory stick

- PC / network communication via Ethernet

- Multi-coefficient linearization of the calibration curve for better accuracy at low loads thus avoiding the use of a second pressure transducer

- Recording facility for up to 9 test profiles for each channel including: type of test (e.g. compression, flexural, indirect tensile), specimen size and shape, load rate, test standard and other general information. Each one of the recorded test profiles can be recalled automatically to save time

- Improved PID algorithm and multi PID selection. Up to 3 different PID settings can be tuned for a variety of materials (e.g. cylinder with neoprene pads, low strength specimens) and test methods (e.g ACV, flexure, indirect tensile).

- Compatible with the newly released Datamanager software, tailored for construction material testing laboratories, for real-time data acquisition, display and management

- Peripheral devices integration with Link-LAB

- Automatic load measurement verification procedure, by connecting suitable load cells and our digital readout unit to PC

- Language selection (including Cyrillic and Chinese)

- Unit selection (kN, ton, lbf)

- USB port for firmware upgrade and safe backup of the original configuration data (PID, calibration, etc.), in case of loss and/or data corruption. The restore of the machine to the factory settings is easy avoiding the need of any technical support.

– Capacity kN : 3000

– Max vertical daylight ,mm* : 350

– Horizontal daylight mm : 370

– Max. piston travel*, mm : 50

– Platen dimensions: 300 mm dia.

– Platen surface hardness : 55.5 HRC (600 HV)

– Platens flatness toll.: 0.03 mm

– Overall dimensions, mm: 1020x475x1550

– Weight approx., kg: 1105

Accessories :

50-C9083 – Distance piece dia 200 x 68 mm. Weight (appx.) 16,7 (2 Set)

50-C9082 – Distance piece dia 200 x 50 mm. Weight (appx.) 12,3 (2 Set)

50-C9080 – Distance piece dia 200 x 30 mm (1 Set)

50-C10B/PR – Upgrading the DIGIMAX, PILOT and AUTOMAX series to incorporate a serial graphic printer in the front panel allowing load/time plot (1 Set)

Informasi Produk : Yudhistira

Hp. 0811 188 6845; 0818 0816 0634

Email : naysite2@gmail.com

Reviews

There are no reviews yet.